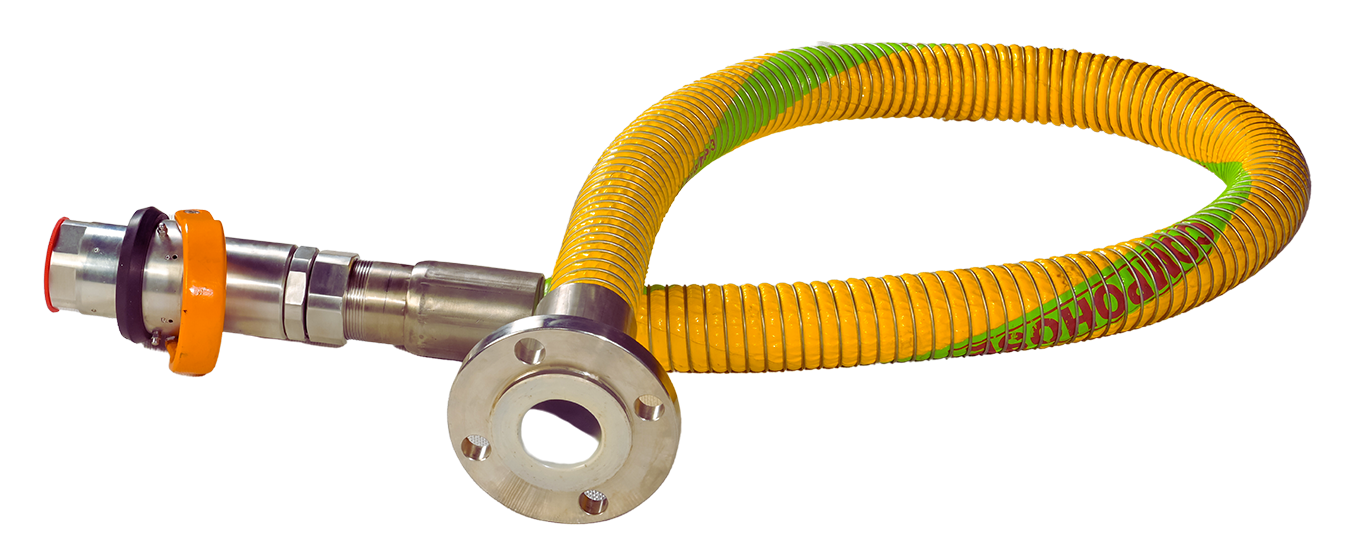

COMPOHOSE® our signature product

Stands as a beacon of engineering excellence

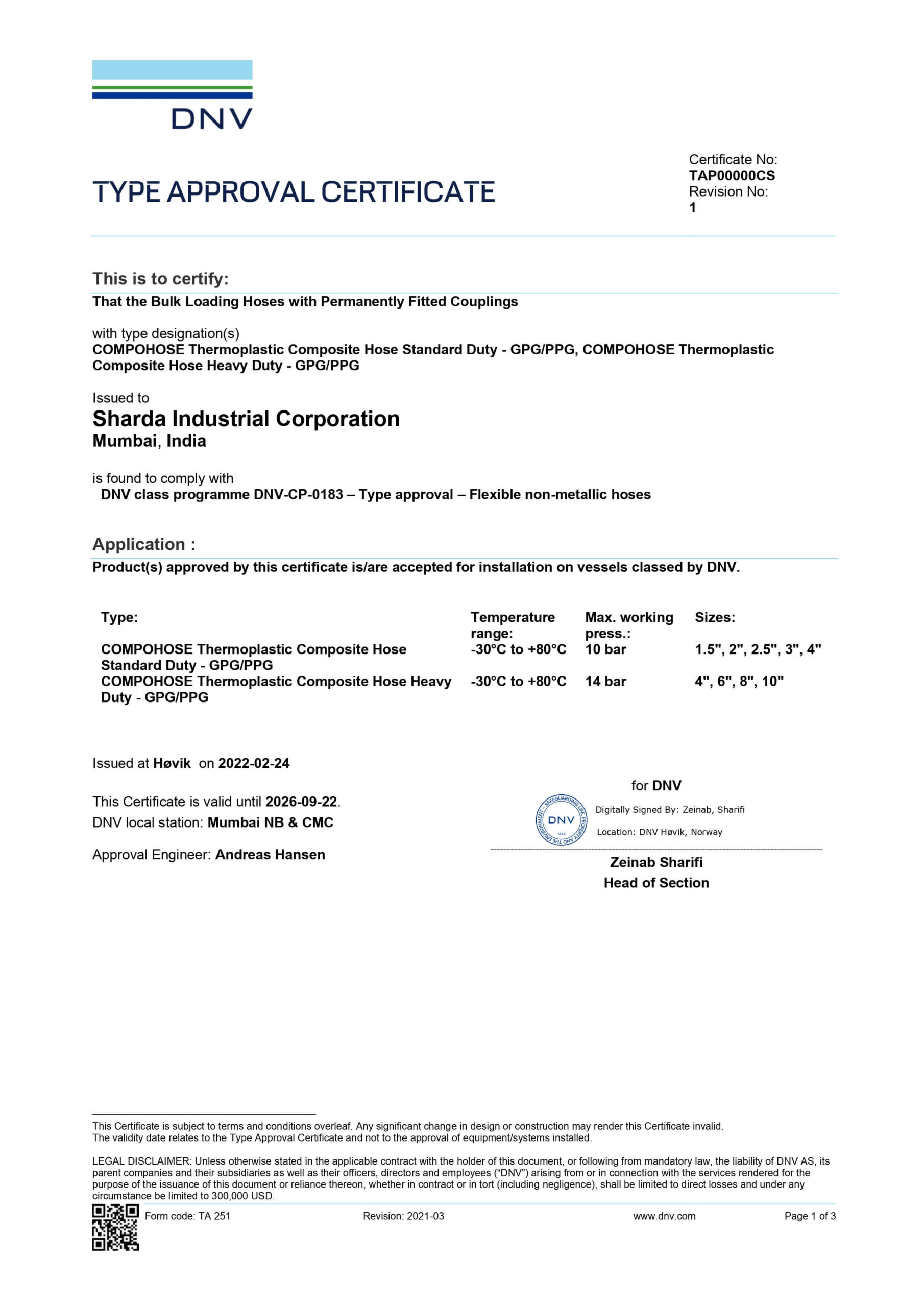

Sharda Industrial Corporation specialises in producing high-quality composite hoses designed for durability, flexibility, and chemical resistance. As pioneers, we are at the forefront of innovation. We are the only firm to have developed 14-inch and 16-inch composite hoses in India. With our sights set on serving global markets and addressing the unique needs of industries handling significant fluid volumes, our expanded product range positions us to become the preferred choice for industry giants worldwide.

COMPOHOSE® is a testament to precision engineering and commitment. Adhering strictly to BSEN 13765 and EN 13766 standards, every detail from the structural inner wire to the protective outer layer speaks of unparalleled quality and design. Stand with the best — experience the power and reliability of our signature product.

Engineered for Excellence and Endurance

- Inner Wire: This acts as the backbone, providing crucial structural support. Whether it's Galvanised Steel, Stainless Steel, or special polypropylene-covered inner wire, every choice is made to ensure optimal chemical compatibility and longevity.

- Inner Fabric or Film Liner: Serving as the hose's first line of defence, it protects against chemical aggression and guards other film layers from wear, all while contributing to its axial and tensile strength.

- Reinforced Fabrics: Incorporated to bolster the hose's pressure-bearing capabilities, ensuring the safety and reliability of fluid transfers.

- Barrier Films: These are resistant to a vast range of solvents, effectively handling both polar and non-polar liquids and ensuring no permeation.

- PVC-Impregnated Cover: An external shield against abrasion and environmental elements like UV rays and ozone, guaranteeing that the hose remains in peak condition even with regular, rigorous use.

- Outer Wire: Complementing the inner wire, this component further amplifies the hose's structural integrity and also offers dual electrical continuity. This effectively dissipates any accumulated electrical charge, thereby mitigating the risk of static flashes.

The Sharda Advantage:Safety, Superiority and Specialised Construction

- Electrical Continuity: A hallmark of safety, our hose assemblies consistently showcase end-to-end electrical continuity. This is realised by adeptly bonding both the inner and outer wires to the end fittings, safeguarding against potential static hazards.

- Materials & Construction: Crafted from Polypropylene, polyamide, and polyester films and fabrics, our hoses cater to specific applications. The polyester outer cover, reinforced with PVC, offers formidable defence against wear and the elements. For those seeking enhanced protection, PTFE liners are available, ready to combat more aggressive chemicals.

- Advantage Over Others: When juxtaposed with traditional rubber or metal hoses, COMPOHOSE® emerges superior. It's not only light and flexible but also uniquely equipped to stave off corrosion, UV damage, and ozone attacks. Its multilayered design ensures longevity and flexibility, even under the most demanding conditions.

Experience the Sharda difference

Innovation Leaders

Trailblazers in producing larger sizes and longer lengths of composite hoses in India.

Quality Assurance

Rigorous quality checks ensuring each hose meets the highest industry standards.

Community Commitment

Actively contributing to social causes, particularly education, in the local community.

Customer-Centric Approach

Continuous product development demonstrates our dedication to meeting the changing demands of the market.

Globally Competitive

Poised to compete on a global scale, offering cutting-edge solutions.