LNG

The Compohose LNG represent a specialized category of hoses meticulously engineered to facilitate the secure and efficient conveyance of cryogenic fluids, including substances like liquefied natural gas (LNG) and liquid nitrogen. These hoses are specifically designed to manage the challenges posed by the extreme cold temperatures at which these fluids exist, ensuring the utmost safety and effectiveness during fluid transfer operations. These hoses are crafted by combining various layers of distinct materials, each serving a unique purpose to enhance overall performance and reliability.

Compliance : Cryogenic hoses are manufactured in accordance to EN 13766 / 2018 Class A Type 2 and Class B type 2

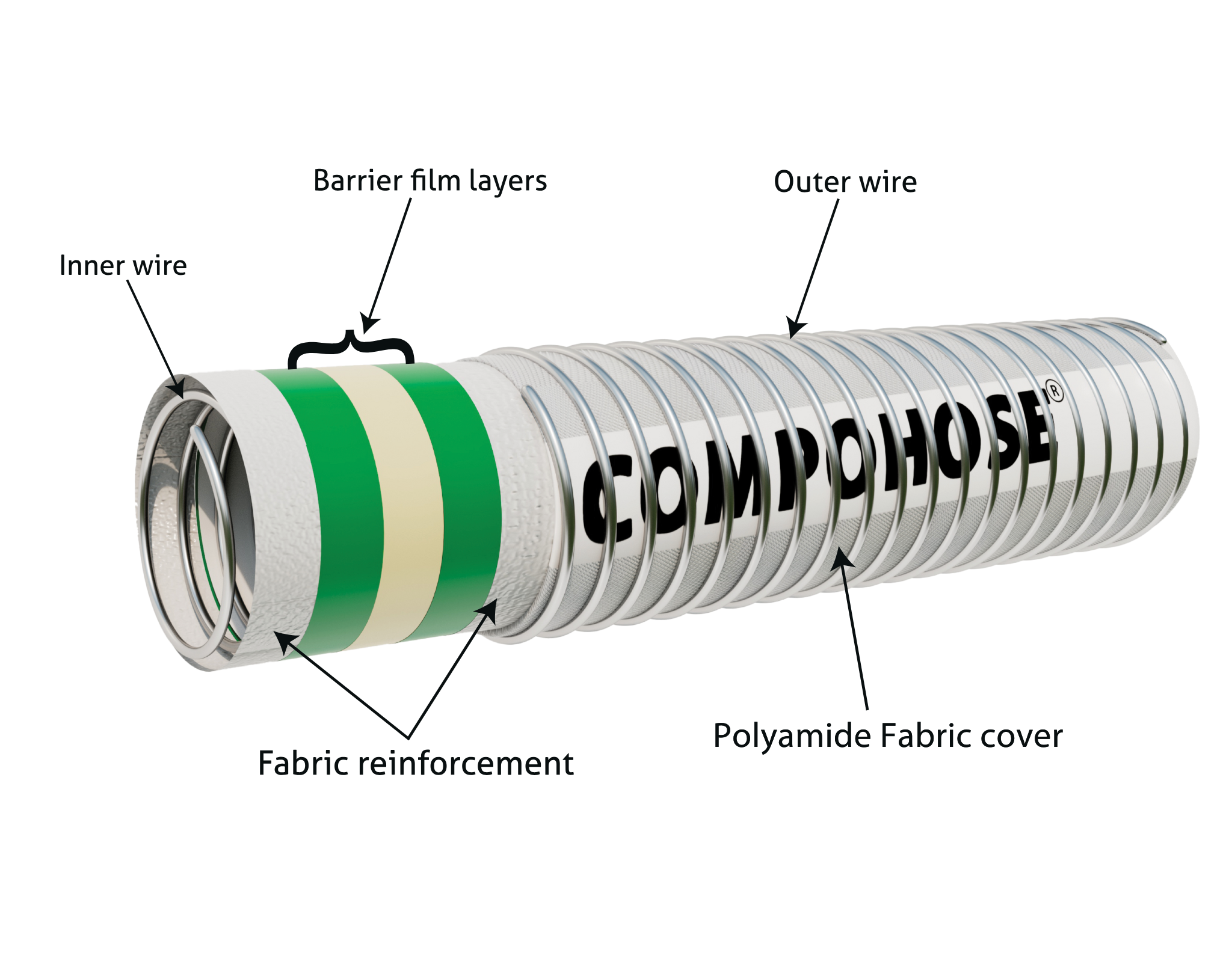

Construction

- Hose Type - SNS

- Inner wire - Stainless steel 316/ 304

- Inner Lining -Multiple layers of Polyamide Fabric and Polyester Barrier Layers

- Outer wire Stainless steel 316/ 304

- Cover - Abrasion-resistant Polyamide Fabric

- End fitting -As per client requirements, externally crimped and swaged

Features

- Tough Polyamide Fabric outer cover resists dragging, wearing, abrasion, UV and ozone resistance ensures maximum durability and safety

- Maximum Compatibility - Handles a wide range of low temperature & cryogenic conveyants.

- Light Weight & Highly Flexible

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Reliability - Tested to industry standards 1.5 times the rated working pressure.

- Suitable for 0.9 Bar Vacuum rating.

- Working Pressure: Class A Type 2 – 13 Bar (185 PSI) & Class B Type 2 – 10.5 Bar (149 PSI)

- Safety factor 4:1 as per EN 13766 / 2018 (can be achieved higher if required)

- Temperature Range for this hose is -196° C to +50° C

Applications

Refrigerated Transport: Cryogenic hoses are essential for loading and unloading fully refrigerated gases like LNG onto transport vehicles such as trucks, railcars, and ships. The hoses can handle the temperature fluctuations during transit and provide a safe means of transfer.

Industrial Gas Plants: Cryogenic hoses are employed in industrial settings for handling various gases used in processes. These hoses are especially valuable when dealing with gases from Gas Group 4, 5, and 7, as they ensure the safe conveyance of potentially hazardous materials.

Liquefied Natural Gas (LNG) Operations: Cryogenic hoses play a role in LNG facilities, ensuring the smooth transfer of LNG between storage tanks, transport vessels, and processing units.

Cryogenic Storage and Distribution: Cryogenic hoses are used in the storage and distribution of cryogenic gases, including liquid nitrogen, oxygen, and argon, for various industrial processes, such as metal fabrication and medical applications.

Specification Table:

| CODE | SIZE | MEAN OD | MAX W.P | MIN BURST | BEND RADIUS | WEIGHT (KG) | MAX LENGTH | |||||||

| NAME | MM | INCH | MM | BAR | PSI | BAR | PSI | MM | INCH | SS | MT | FT | ||

| LNG05SS25 | 25 | 1” | 37 | 13 | 200 | 52.5 | 800 | 200 | 8 | 1.10 | 30 | 100 | ||

| LNG05SS38 | 38 | 1.5” | 51 | 13 | 200 | 52.5 | 800 | 200 | 8 | 1.80 | 30 | 100 | ||

| LNG05SS50 | 50 | 2” | 65 | 13 | 200 | 52.5 | 800 | 225 | 9 | 2.50 | 30 | 100 | ||

| LNG05SS65 | 65 | 2.5” | 77 | 13 | 200 | 52.5 | 800 | 225 | 9 | 3.90 | 30 | 100 | ||

| LNG05SS75 | 75 | 3” | 90 | 13 | 200 | 52.5 | 800 | 350 | 14 | 4.20 | 30 | 100 | ||

| LNG05SS100 | 100 | 4” | 121 | 13 | 200 | 52.5 | 800 | 400 | 16 | 5.30 | 30 | 100 | ||

| LNG05SS150 | 150 | 6” | 179 | 13 | 200 | 52.5 | 800 | 575 | 23 | 13.50 | 30 | 100 | ||

| LNG05SS200 | 200 | 8” | 233 | 13 | 200 | 52.5 | 800 | 800 | 32 | 16.40 | 30 | 100 | ||

| LNG05SS250 | 250 | 10” | 284 | 13 | 200 | 52.5 | 800 | 1000 | 40 | 21.30 | 15 | 50 | ||

| LNG05SS300 | 300 | 12” | 333 | 13 | 200 | 52.5 | 800 | 1200 | 48 | 26.70 | 15 | 50 | ||

*Higher burst pressure can be achieved on special request

Safety Standards

Rigorous Safety Testing

COMPOHOSE assemblies undergo comprehensive testing, conducted at 1.5 times the rated Working Pressure (W.P). This stringent testing adheres to the EN 13766 standard, ensuring a paramount level of safety and reliability.

Provision of Manufacturer's Test Certificate

With each supply of COMPOHOSE composite hose assemblies, a Manufacturer's Test Certificate is included. This certificate serves as a confirmation of the product's quality and compliance with safety standards, providing added assurance to users.

Clear Burst Pressure Specification

The burst pressure of the composite hose is explicitly indicated for ambient temperature conditions. This vital information enhances safety awareness and empowers users to operate within secure pressure limits.

Effective Electrical Continuity

The composite hose's electrical continuity is assured through the integration of two bonded wires connected to the end fitting. This innovative design promotes the dissipation of accumulated electrical charges, mitigating the risk of static flashes and associated hazards.