LPG

The Compohose LPG is an advanced hose specifically engineered for optimal performance in handling liquefied petroleum gas (LPG). It boasts a unique design featuring multiple layers of different polymers combined with spirals made from high-quality stainless steel 316. Utilizing state-of-the-art manufacturing technology, this composite hose stands out as an excellent and safe solution for supporting cryogenic products. Its cutting-edge design and advanced materials make it a versatile and dependable choice for industries that demand precision, durability, and safety in the handling of cryogenic products.

Compliance : Cryogenic hoses are manufactured in accordance to EN 13766 / 2018 Class A Type 1 and Class B type 1

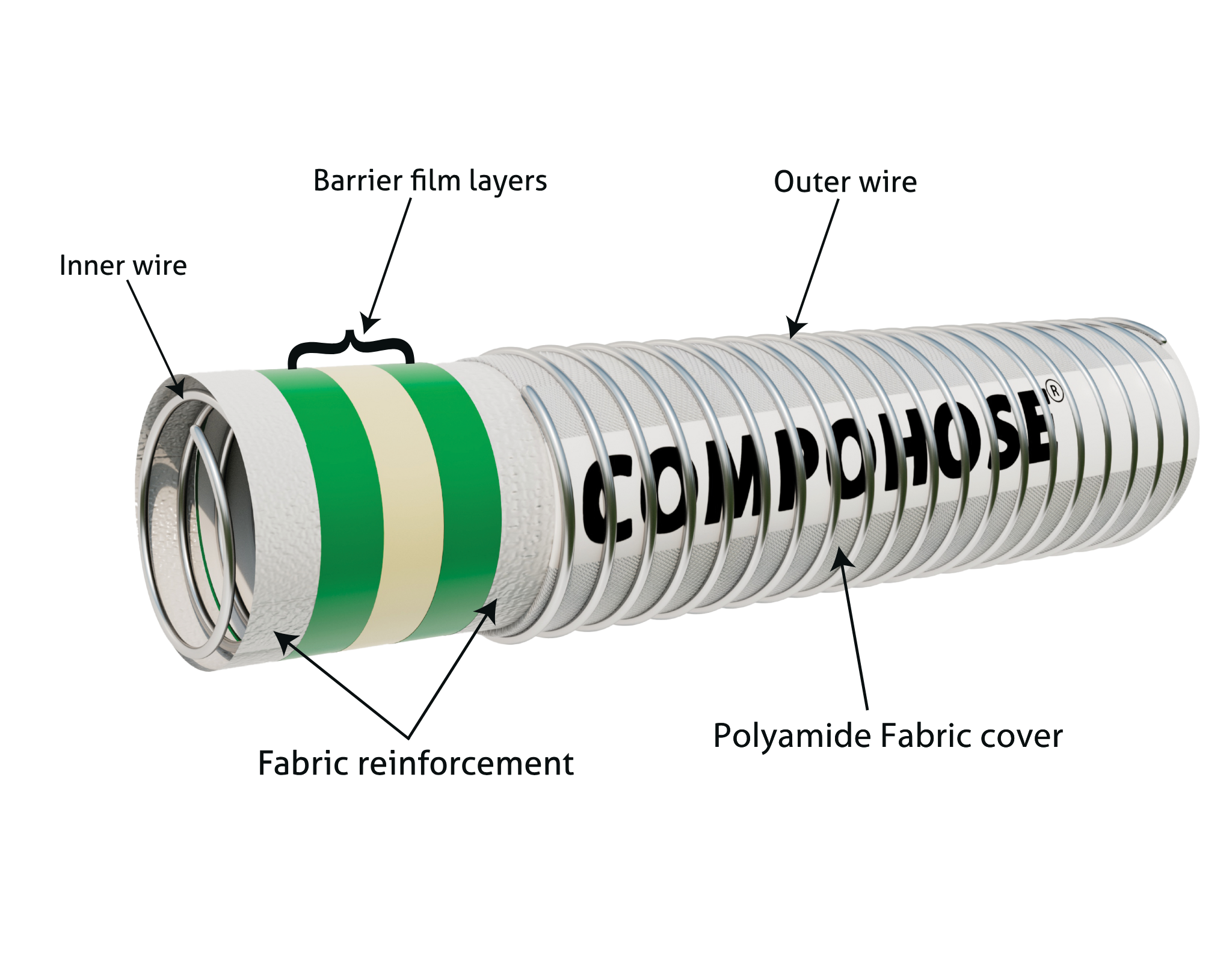

Construction

- Hose Type - SNS

- Inner wire - Stainless Steel 316/ 304

- Inner Lining -Multiple layers of Polyamide Fabric and Polyester Barrier Layers

- Outer wire -Stainless Steel 316/ 304

- Cover - Abrasion-resistant Polyamide Fabric

- End fitting -As per client requirements, externally crimped and swaged

Features

- Tough Polyamide Fabric outer cover resists dragging, wearing, abrasion, UV and ozone resistance ensures maximum durability and safety

- Maximum Compatibility - Handles a wide range of low temperature & cryogenic conveyants.

- Light Weight & Highly Flexible

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Reliability - Tested to industry standards 1.5 times the rated working pressure.

- Suitable for 0.9 Bar Vacuum rating.

- Working Pressure: Class A Type 1- 25 Bar (355 PSI) & Class B Type 1- 20 Bar (284 PSI)

- Safety factor 4:1 as per EN 13766 / 2018 (can be achieved higher if required)

- Temperature Range for this hose is -50° C to +45° C (-58° F to +113° F)

Applications

LPG Terminal Operations : In LPG terminals and storage facilities, Compohose LPG are crucial for safe and efficient transfer of fully refrigerated LPG. Compohose can withstand the extreme low temperatures of liquefied gases, ensuring reliable charge and discharge operations.

Truck Loading and Unloading : Compohose LPG is used for the loading and unloading of LPG or ammonia from trucks. The hose ensures a safe and efficient transfer of the gases between the storage tanks at the truck and the storage facilities at the distribution points.

Wagon Transfer : In railway transport, Compohose LPG is employed for transferring liquefied gases between wagons and storage facilities. This is crucial for the efficient transportation of large quantities of LPG or ammonia via rail.

Marine Applications : Compohose LPG is utilized in marine vessels for transferring liquefied gases during bunkering operations. These hoses play a critical role in the safe and controlled transfer of gases from storage tanks onshore or from one vessel to another.

Ship-to-Ship Operations : Ship-to-ship operations involve the transfer of LPG or ammonia from one vessel to another. Compohose LPG ensures a secure and reliable connection between the bunkering facilities on both ships, allowing for the efficient transfer of gases while minimizing the risk of leaks or accidents.

Specification Table :

| CODE | SIZE | MEAN OD | MAX W.P | MIN BURST | BEND RADIUS | WEIGHT (KG) | MAX LENGTH | |||||||

| NAME | MM | INCH | MM | BAR | PSI | BAR | PSI | MM | INCH | SS | MT | FT | ||

| LPG05SS25 | 25 | 1” | 37 | 25 | 200 | 100 | 800 | 200 | 8 | 1.10 | 30 | 100 | ||

| LPG05SS38 | 38 | 1.5” | 51 | 25 | 200 | 100 | 800 | 200 | 8 | 1.40 | 30 | 100 | ||

| LPG05SS50 | 50 | 2” | 65 | 25 | 200 | 100 | 800 | 225 | 9 | 1.70 | 30 | 100 | ||

| LPG05SS65 | 65 | 2.5” | 77 | 25 | 200 | 100 | 800 | 225 | 9 | 2.40 | 30 | 100 | ||

| LPG05SS75 | 75 | 3” | 90 | 25 | 200 | 100 | 800 | 350 | 14 | 3.00 | 30 | 100 | ||

| LPG05SS100 | 100 | 4” | 121 | 25 | 200 | 100 | 800 | 400 | 16 | 5.20 | 30 | 100 | ||

| LPG05SS150 | 150 | 6” | 179 | 25 | 200 | 100 | 800 | 575 | 23 | 11.50 | 30 | 100 | ||

| LPG05SS200 | 200 | 8” | 233 | 25 | 200 | 100 | 800 | 800 | 32 | 16.40 | 30 | 100 | ||

| LPG05SS250 | 250 | 10” | 284 | 25 | 200 | 100 | 800 | 1000 | 40 | 21.30 | 15 | 50 | ||

| LPG05SS300 | 300 | 12” | 333 | 25 | 200 | 100 | 800 | 1200 | 48 | 26.70 | 15 | 50 | ||

*Higher burst pressure can be achieved on special request

Safety Standards

Rigorous Safety Testing

COMPOHOSE assemblies undergo comprehensive testing, conducted at 1.5 times the rated Working Pressure (W.P). This stringent testing adheres to the EN 13766 standard, ensuring a paramount level of safety and reliability.

Provision of Manufacturer's Test Certificate

With each supply of COMPOHOSE composite hose assemblies, a Manufacturer's Test Certificate is included. This certificate serves as a confirmation of the product's quality and compliance with safety standards, providing added assurance to users.

Clear Burst Pressure Specification

The burst pressure of the composite hose is explicitly indicated for ambient temperature conditions. This vital information enhances safety awareness and empowers users to operate within secure pressure limits.

Effective Electrical Continuity

The composite hose's electrical continuity is assured through the integration of two bonded wires connected to the end fitting. This innovative design promotes the dissipation of accumulated electrical charges, mitigating the risk of static flashes and associated hazards.