Multi Dock Oil Suction: Heavy Duty

The Multi Dock Oil Suction Heavy Duty Composite Hoses have been meticulously crafted to excel in the seamless and dependable conveyance of substances such as petroleum derivatives, oils, and chemicals across a spectrum of maritime and industrial scenarios. Engineered with precision, these hoses boast a repertoire of vital attributes that render them exceptionally well-suited for rigorous and demanding operations. Their efficiency, reliability, versatility, and durability make them an indispensable asset in numerous marine and industrial applications, where the secure and efficient transportation of critical substances is paramount.

Compliance : Multi Dock Oil Suction hoses are manufactured in accordance to EN 13765 / 2018 Type 3.

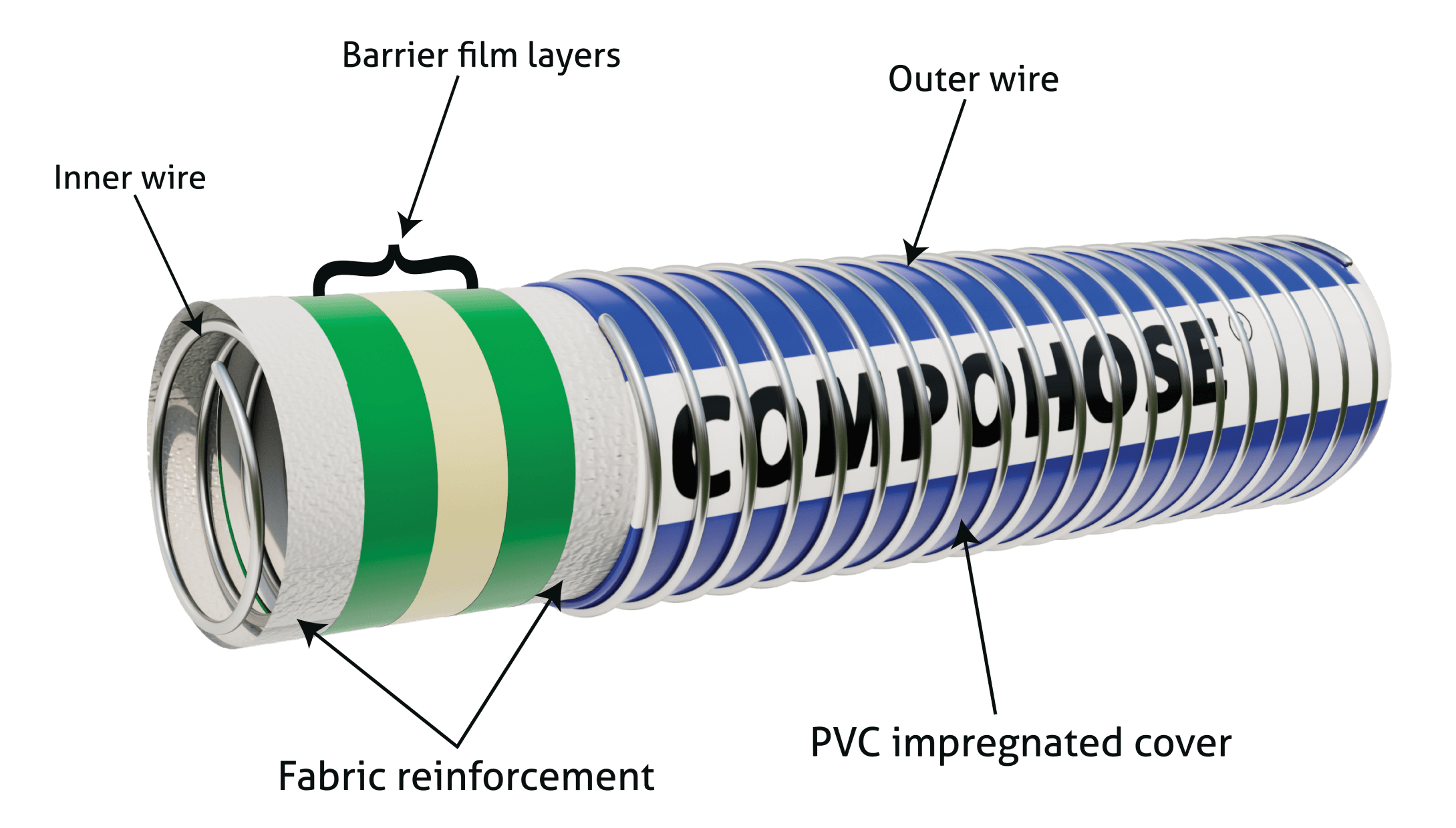

Construction

- Hose Type - GPG, SPG, SPS

- Inner wire - Galvanised Steel / Stainless Steel 304, 316

- Inner Lining - Multiple layers of polypropylene fabric, film and polyester barrier layers

- Outer wire - Galvanised Steel / Stainless Steel 304, 316

- Cover - Abrasion-resistant PVC impregnated fabric

- End fitting - As per client requirements, externally crimped and swaged

Features

- Polypropylene liner with heavy duty polypropylene carcass for maximum chemical resistance.

- Tough PVC outer cover resists dragging, wearing, abrasion, UV and ozone resistance ensures maximum durability and safety.

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Choice of Galvanised and Stainless Steel outer wire can be provided.

- Suitable for 0.9 Bar Vacuum rating

- Working Pressure 14 Bar (200 PSI)

- Safety factor 4:1 as per EN 13765 / 2018 (can be achieved higher if required)

- Temperature Range for this hose is -30° C to +100° C (-22° F to +212° F)

Applications

Marine and Offshore

Multi Dock Oil Suction Heavy Duty Composite Hoses are commonly used in marine and offshore applications for transferring crude oil, refined petroleum products, and other chemicals between ships, docks, and storage facilities. They can withstand the harsh conditions of the sea, including saltwater exposure and abrasive materials.

Bulk Storage Terminals

At large storage terminals, these hoses can be used to transfer bulk quantities of various liquids from storage tanks to trucks, ships, or pipelines. The hoses' durability and flexibility are beneficial for managing the transfer of products over long distances.

Oil Refineries

These hoses are suitable for transferring various petroleum-based products within oil refineries. They can be used to move crude oil, refined products like gasoline and diesel, and intermediate chemicals between different stages of the refining process.

Ship-to-Ship Transfers

The heavy-duty composite hose is suitable for transferring crude oil between two ships at sea. Its robust construction and flexibility make it ideal for dynamic conditions during ship-to-ship transfers.

Barges

The heavy-duty composite hose is well-suited for loading and unloading operations involving barges. It can handle a variety of liquids, including oils and chemicals.

Bunkering

The heavy-duty composite hose is suitable for bunkering operations where large quantities of fuel (such as marine diesel or heavy fuel oil) need to be transferred from a bunker barge or storage facility to the vessel.

Specification Table:

| CODE | SIZE | MEAN OD | MAX W.P | MIN BURST | BEND RADIUS | WEIGHT (KG) | MAX LENGTH | |||||

| NAME | MM | INCH | MM | BAR | PSI | BAR | PSI | MM | INCH | GG & SG | MT | FT |

| 02GG25 | 25 | 1” | 37 | 14 | 200 | 56 | 800 | 200 | 8 | 1.00 | 30 | 100 |

| 02GG38 | 38 | 1.5” | 51 | 14 | 200 | 56 | 800 | 200 | 8 | 1.35 | 30 | 100 |

| 02GG50 | 50 | 2” | 65 | 14 | 200 | 56 | 800 | 225 | 9 | 1.50 | 30 | 100 |

| 02GG65 | 65 | 2.5” | 77 | 14 | 200 | 56 | 800 | 225 | 9 | 2.10 | 30 | 100 |

| 02GG75 | 75 | 3” | 90 | 14 | 200 | 56 | 800 | 350 | 14 | 3.00 | 30 | 100 |

| 02GG100 | 100 | 4” | 121 | 14 | 200 | 56 | 800 | 400 | 16 | 5.60 | 30 | 100 |

| 02GG150 | 150 | 6” | 179 | 14 | 200 | 56 | 800 | 575 | 23 | 11.00 | 30 | 100 |

| 02GG200 | 200 | 8” | 233 | 14 | 200 | 56 | 800 | 800 | 32 | 16.40 | 30 | 100 |

| 02GG250 | 250 | 10” | 284 | 14 | 200 | 56 | 800 | 1000 | 40 | 21.30 | 15 | 50 |

| 02GG300 | 300 | 12” | 333 | 14 | 200 | 56 | 800 | 1200 | 48 | 27.00 | 15 | 50 |

*Higher burst pressure can be achieved on special request

Safety Standards

Rigorous Safety Testing

COMPOHOSE assemblies undergo comprehensive testing, conducted at 1.5 times the rated Working Pressure (W.P). This stringent testing adheres to the EN 13765 standard, ensuring a paramount level of safety and reliability.

Provision of Manufacturer's Test Certificate

With each supply of COMPOHOSE composite hose assemblies, a Manufacturer's Test Certificate is included. This certificate serves as a confirmation of the product's quality and compliance with safety standards, providing added assurance to users.

Clear Burst Pressure Specification

The burst pressure of the composite hose is explicitly indicated for ambient temperature conditions. This vital information enhances safety awareness and empowers users to operate within secure pressure limits.

Effective Electrical Continuity

The composite hose's electrical continuity is assured through the integration of two bonded wires connected to the end fitting. This innovative design promotes the dissipation of accumulated electrical charges, mitigating the risk of static flashes and associated hazards.