Multi Oil Suction: Standard Duty

A multi-oil suction standard duty composite hose is a type of flexible hose designed for use in industrial applications where the transfer of multiple types of oils and petroleum-based products is required. This hose is constructed using a composite material, typically consisting of multiple layers of different materials such as thermoplastic and reinforcing materials like polyester. These layers are combined to create a hose that offers specific properties and performance characteristics.

Compliance : Multi Oil Suction hoses are manufactured in accordance to EN 13765 / 2018 Type 2.

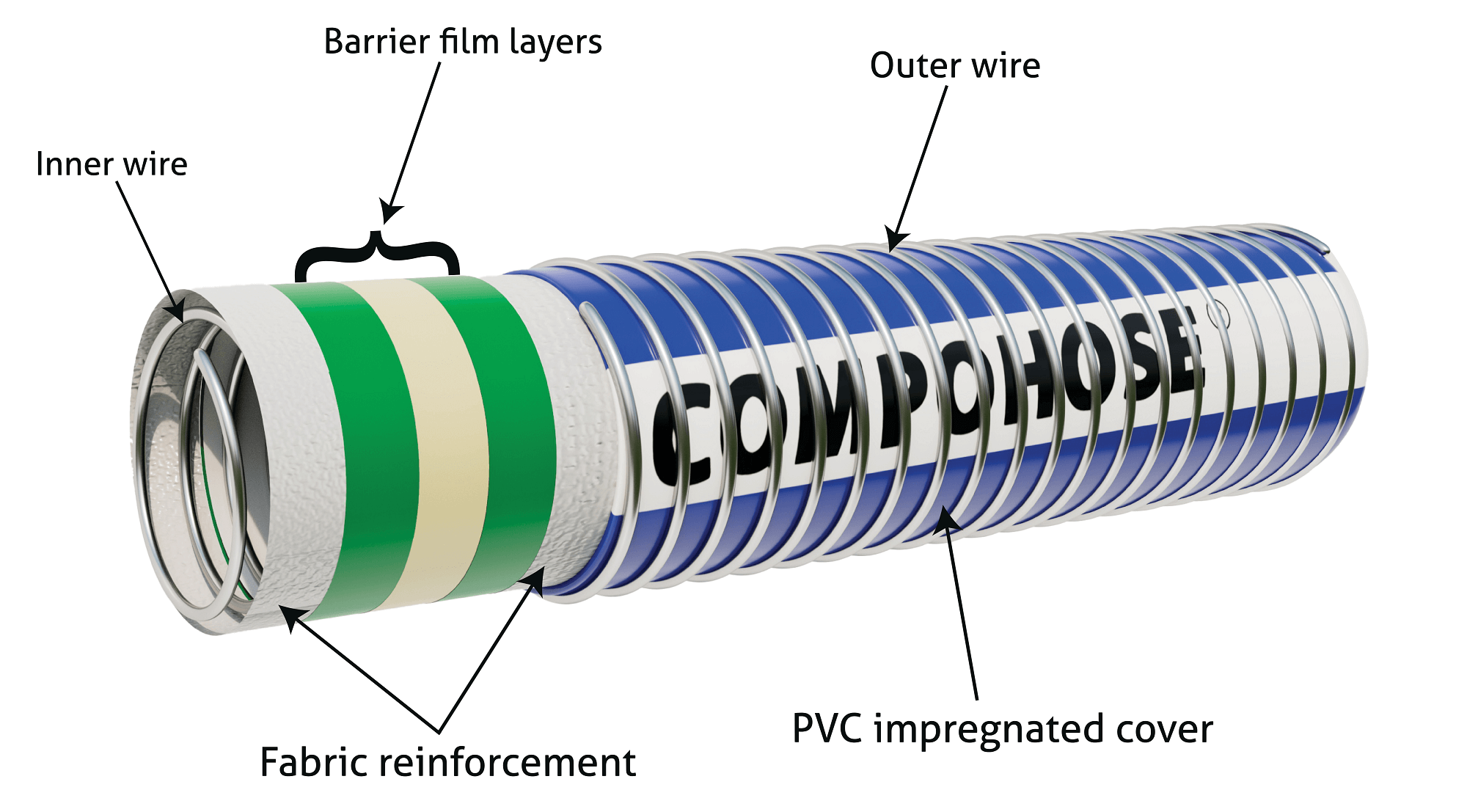

Construction

- Hose Type - GPG, APG, SPG

- Inner wire - Galvanised Steel / Stainless Steel 304, 316 / Aluminium

- Inner Lining - Multiple layers of polypropylene fabric, film and polyester barrier layers

- Outer wire - Galvanised Steel / Stainless Steel 304, 316 / Aluminium

- Cover - Abrasion-resistant PVC impregnated fabric

- End fitting - As per client requirements, externally crimped and swaged

Features

- Compatible for safe handling of all types of oil based, 100% aromatic content and other non-aggressive chemicals.

- Light Weight & High Flexibility makes it easy to handle in loading and unloading.

- Tough PVC outer cover resists dragging, wearing, abrasion, UV and ozone resistance ensures maximum durability and safety.

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Suitable for 0.9 Bar Vacuum rating.

- Working Pressure 10 Bar (150 PSI)

- Temperature Range for this hose is -30° C to +100° C (-22° F to +212° F)

- Safety factor 4:1 as per EN 13765 / 2018 (can be achieved higher if required)

Applications

Oil Transfer

The primary application of multi oil suction hoses is the transfer of various types of oils and petroleum-based liquids. This includes loading and unloading tank trucks, railcars, and storage tanks.

Marine Operations

These hoses are commonly used in maritime industries for tasks such as bunkering (fueling) ships, transferring oil between vessels, and handling oil spill response.

Industrial Processes

They find applications in industrial processes where the safe and efficient transfer of oils and fuels is necessary. This can include machinery maintenance, factory operations, and fuel supply to power generators.

Oil Refineries

Multi oil suction hoses are used in refineries for transferring crude oil, intermediate products, and refined petroleum products between different process units.

Chemical Plants

In chemical plants, these hoses may be used to transport oil-based chemicals, solvents, and other substances.

Emergency Response

In emergency situations, these hoses can be used for oil spill cleanup and containment, preventing environmental damage.

Tank Storage Facilities

They play a role in transferring oils and fuels to and from storage tanks in various facilities.

Specification Table:

| CODE | SIZE | MEAN OD | MAX W.P | MIN BURST | BEND RADIUS | WEIGHT (KG) | MAX LENGTH | |||||||

| NAME | MM | INCH | MM | BAR | PSI | BAR | PSI | MM | INCH | GG | MT | FT | ||

| 01GG25 | 25 | 1” | 37 | 10 | 150 | 40 | 600 | 125 | 5 | 1.00 | 30 | 100 | ||

| 01GG38 | 38 | 1.5” | 50 | 10 | 150 | 40 | 600 | 150 | 6 | 1.35 | 30 | 100 | ||

| 01GG50 | 50 | 2” | 65 | 10 | 150 | 40 | 600 | 200 | 8 | 1.50 | 30 | 100 | ||

| 01GG65 | 65 | 2.5” | 76 | 10 | 150 | 40 | 600 | 200 | 8 | 1.70 | 30 | 100 | ||

| 01GG75 | 75 | 3” | 89 | 10 | 150 | 40 | 600 | 300 | 12 | 2.40 | 30 | 100 | ||

| 01GG100 | 100 | 4” | 119 | 10 | 150 | 40 | 600 | 400 | 16 | 3.70 | 30 | 100 | ||

| 01GG150 | 150 | 6” | 178 | 10 | 150 | 40 | 600 | 575 | 23 | 8.60 | 30 | 100 | ||

| 01GG200 | 200 | 8” | 231 | 10 | 150 | 40 | 600 | 800 | 32 | 14.60 | 30 | 100 | ||

| 01GG250 | 250 | 10” | 282 | 10 | 150 | 40 | 600 | 1000 | 40 | 19.10 | 15 | 50 | ||

| 01GG300 | 300 | 12” | 331 | 10 | 150 | 40 | 600 | 1200 | 48 | 24.70 | 15 | 50 | ||

| 01GG350 | 350 | 14” | 380 | 10 | 150 | 40 | 600 | 1400 | 56 | 26.60 | 6 | 20 | ||

| 01GG400 | 400 | 16” | 442 | 10 | 150 | 40 | 600 | 1600 | 64 | 29.80 | 6 | 20 | ||

*Higher burst pressure can be achieved on special request

Safety Standards

Rigorous Safety Testing

COMPOHOSE assemblies undergo comprehensive testing, conducted at 1.5 times the rated Working Pressure (W.P). This stringent testing adheres to the EN 13765 standard, ensuring a paramount level of safety and reliability.

Provision of Manufacturer's Test Certificate

With each supply of COMPOHOSE composite hose assemblies, a Manufacturer's Test Certificate is included. This certificate serves as a confirmation of the product's quality and compliance with safety standards, providing added assurance to users.

Clear Burst Pressure Specification

The burst pressure of the composite hose is explicitly indicated for ambient temperature conditions. This vital information enhances safety awareness and empowers users to operate within secure pressure limits.

Effective Electrical Continuity

The composite hose's electrical continuity is assured through the integration of two bonded wires connected to the end fitting. This innovative design promotes the dissipation of accumulated electrical charges, mitigating the risk of static flashes and associated hazards.