Quality Assurance

Upholding global standards

Our products undergo rigorous evaluations to meet and exceed industry standards and regulatory benchmarks. Here are the certifications and standards that our composite hoses adhere to:

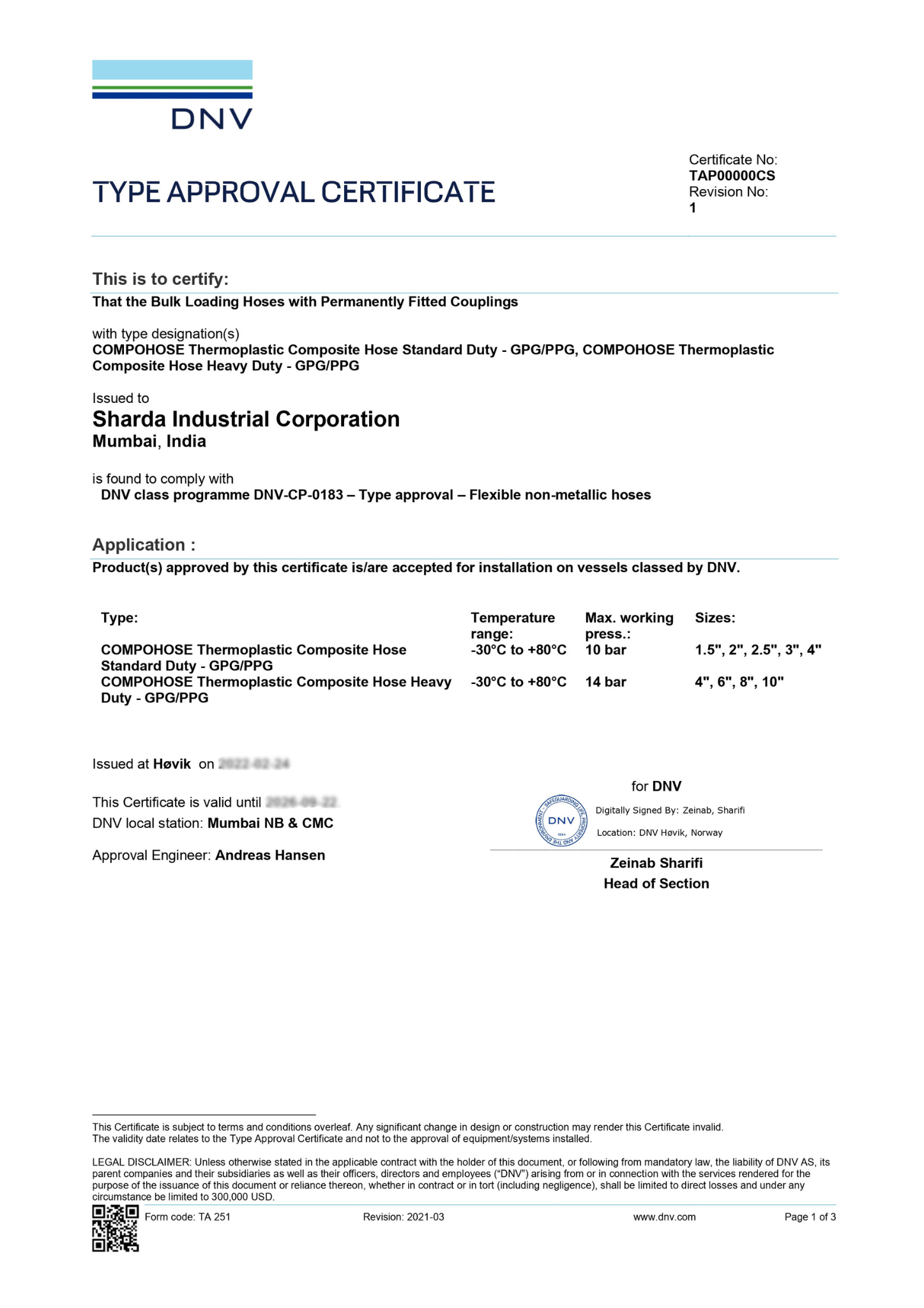

BS EN 13765: 2018

An international standard for which we have received the DNV "Type Approval Certificate" for our COMPOSHOSE® hoses

NAHAD

COMPOSHOSE® hoses are manufactured in accordance with the recommendations outlined in NAHAD guidelines.

COMPOSHOSE® hoses are manufactured in accordance with the Directives ATEX 2014/34/EU for harmonization of Essential Health & Safety Requirements (EHSR).

ISO 9001:2015

Validates our quality management systems, ensuring we consistently produce and deliver high-quality products.

ISO 14001: 2015

Demonstrates our commitment to environmental responsibility in all our processes.

ISO 45001:2018

Ensures our management systems are designed with an emphasis on occupational health and safety.

Our commitment to quality and excellence takes another significant step as we work diligently towards obtaining the EN 13766 type approval certificate for our composite hoses. Catering especially to Cryogenic applications, this globally recognised certification asserts our product’s adherence to stringent quality and performance metrics, promising reliability through rigorous testing as per the EN 13766 specifications.

Certificates

Quality Assurance and Testing Processes

At Sharda Industrial Corporation, we distinguish ourselves from competitors through several key practices and features:

High-Quality Materials

We use top-tier materials in the production of our composite hoses. Our selective choice of materials, known for their superior chemical resistance, high tensile strength, and durability, ensures the production of hoses that perform exceptionally under the most demanding conditions.

Advanced Composite Construction

Our manufacturing process utilises advanced composite construction techniques, resulting in hoses composed of multiple layers of thermoplastic fabrics and films, with an internal wire helix. This construction boosts the hose's resilience to chemicals, abrasion, and extreme temperatures, while also enhancing its flexibility and strength.

Customisation Options

Understanding that different industries have unique needs, we offer an extensive range of customization options for our composite hoses. Clients can select from a variety of sizes, lengths, end fittings, and specifications, ensuring an optimal fit for their specific applications.

Rigorous Quality Control

To deliver superior quality products, we implement stringent quality control measures throughout our manufacturing process. Our hoses are rigorously tested for pressure resistance, leakages, dimensional accuracy, and other performance parameters, ensuring only reliable and high-performing hoses reach our customers.

Application Versatility

Our composite hoses are designed to be adaptable to a wide range of applications. Industries like petrochemicals, oil and gas, chemicals, food processing, and pharmaceuticals utilise our hoses for their adaptability to handle various media, including aggressive chemicals, fuels, oils, gases, and liquids.

Technical Expertise

Our extensive experience and technical expertise in composite hose manufacturing allows us to continuously improve our product design, functionality, and performance, providing our customers with innovative solutions and valuable technical support.

Commitment to Customer Satisfaction

We place a strong emphasis on customer satisfaction, striving to build long-term relationships with our clients by understanding their needs and providing personalised service. This includes offering prompt customer support, technical guidance, and timely deliveries.

Quality Assurance Process

To ensure our products’ quality, we adhere to strict measures and practices:

Compliance with Standards

Our composite hoses meet high-quality management systems like international BS EN 13765: 2018 standards approved by DNV “Type Approval Certificate”, NAHAD along with ISO 9001:2015, ISO 14001: 2015, ISO 45001:2018.

Raw Material Selection

We meticulously select high-quality raw materials for manufacturing our composite hoses, including choosing appropriate reinforcements, such as high-strength fabric like polyester, polypropylene, or polyamide and selecting compatible elastomers for the inner and outer layers.

Stringent Testing

Our products undergo rigorous testing at various stages of the manufacturing process to ensure their quality and performance. Tests include burst pressure, tensile strength, flexibility, leakage, and chemical resistance. Hydrostatic pressure testing is also performed to ensure our hoses can withstand the specified pressure ratings.

Quality Control Systems

We have robust quality control systems in place to oversee and regulate the production process. These involve quality checkpoints at different stages, such as incoming raw materials inspection, in-process inspections, and final product inspections.

Traceability and Documentation

We maintain comprehensive records and documentation throughout our manufacturing process. This includes documenting raw material specifications, manufacturing parameters, test results, and other relevant information, allowing for easy identification and resolution of any quality-related issues that may arise.