Aviation Fuel

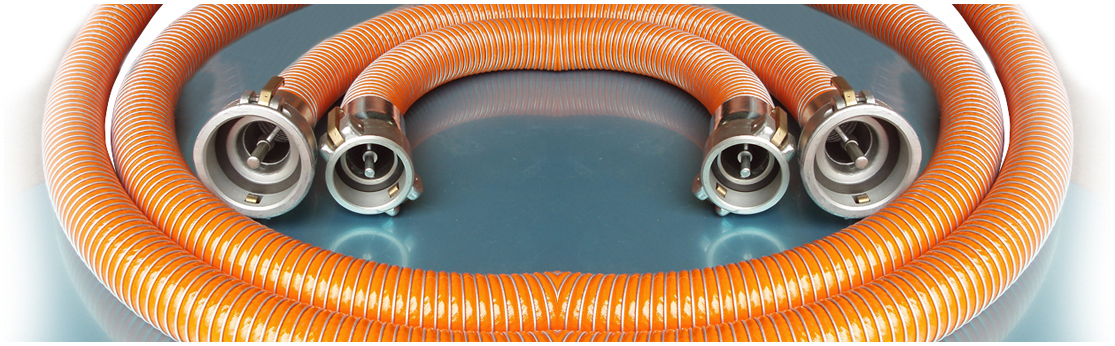

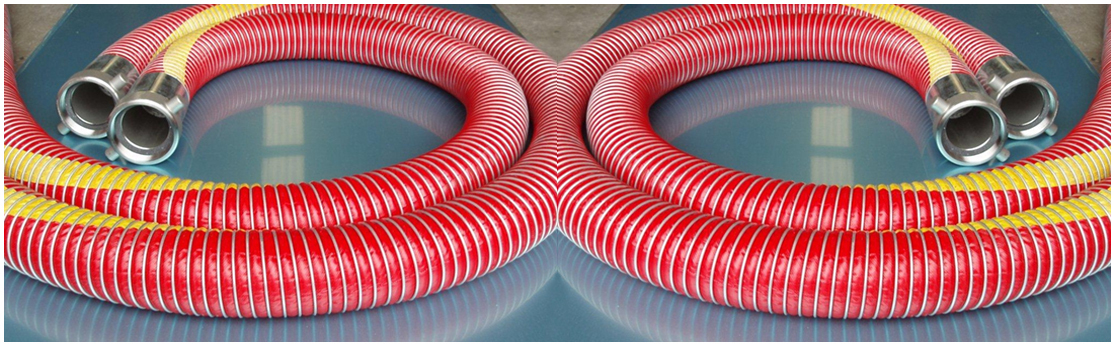

STANDARD DUTY-SPG

Standard Duty Aviation Fuel Suction and Discharge composite hoses are design for handling Aviation fuel, lubricant where light weight and high flexibility is required.

APPLICATION

hoses and hose assemblies are recommended for Rail Tank Wagon, Tank

Truck Loading and Unloading, Storage tanks transfers and other standard

duty applications.

hoses and hose assemblies are recommended for Rail Tank Wagon, Tank

Truck Loading and Unloading, Storage tanks transfers and other standard

duty applications.

COMPLIANCE

Standard Duty Aviation fuel suction and discharge composite hoses are manufactured in accordance to EN13765/2010 Type 2.

PRODUCT HANDLE

Specially for Aviation Fuel, Superior Kerosene & also can be used for gasoline, diesel fuel, paraffin, kerosene, lubricating oils and 100% aromatics as well as black oils and heavy lubricants and solvent not recommended for corrosive and aggressive chemicals.

FEATURES

- Complete product compatibility for safe handling of Aviation Fuel & Superior Kerosene.

- Light Weight & Highly Flexible makes it easy to handle in loading and delivery.

- Tough PVC outer cover resists to dragging, wear, abrasion, UV and ozone resistance having maximum durability and safety.

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Suitable for 0.9 Bar Vacuum rating.

CONSTRUCTIONS

- INNER WIRE : Stainless steel 304 / 316

- OUTER WIRE : High tensile strength galvanized steel

- CARCASS : Multiple layers of polypropylene fabric, film and polyester barrier layers

- COVER : Abrasion resistant PVC impregnated fabric

- TEMPERATURE RANGE : -30°C to +80°C

- END FITTING : As per client requirement which will be externally crimped or swaged

|

SIZE |

MAX W.P |

MIN. BURST |

BEND RADIUS |

WEIGHT |

MAX. LENGTH |

|||||

|

MM |

INCH |

BAR |

PSI |

BAR |

PSI |

MM |

INCH |

KG/MT |

LB/FT |

MT |

|

38 |

1.5“ |

10 |

150 |

40 |

600 |

85 |

3.5 |

1.4 |

0.9 |

20 |

|

50 |

2“ |

10 |

150 |

40 |

600 |

125 |

5 |

1.7 |

1.1 |

20 |

|

65 |

2.5“ |

10 |

150 |

40 |

600 |

150 |

6 |

2.4 |

1.6 |

20 |

|

75 |

3“ |

10 |

150 |

40 |

600 |

175 |

7 |

2.8 |

1.9 |

20 |

|

100 |

4“ |

10 |

150 |

40 |

600 |

250 |

10 |

3.7 |

2.5 |

20 |

SAFETY

assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with EN 13765.

assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with EN 13765.- Manufacturer test certificate will be provided with the supply.

- Burst pressure Indicated is at ambient temperature.

- Electrically continuity is achieved by the two wire bonded to the end fitting, this helps dissipate accumulated charge and to avoid static flash.