Multihigh Temperature

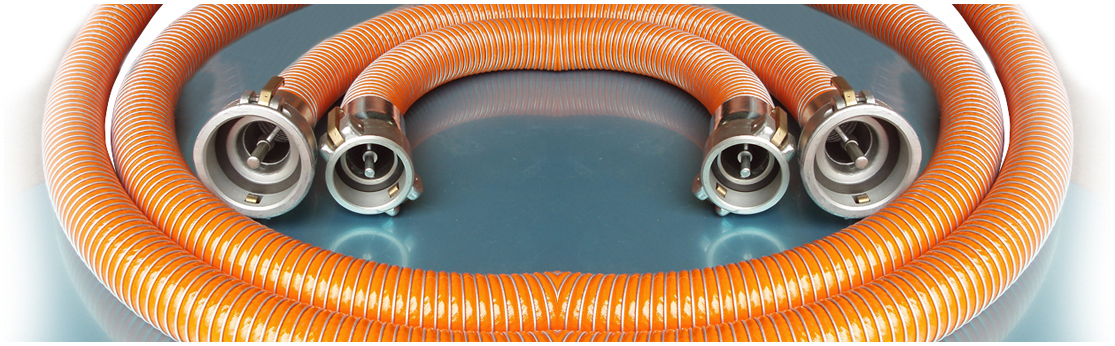

STANDARD DUTY

Multihigh Temp composite hose is designed for handling hot viscous petroleum by products and where high temperature upto +180°C are requirement.

APPLICATION

The  assembly are recommended for handling hot viscous petroleum by products

and where high temperature upto +180°C are requirement. The Spiral

wound high tensile galvanized iron / Stainless Steel inner wire and

outer wire for providing strength & the flexibility to maintain hose

integrity under stress and strain.

assembly are recommended for handling hot viscous petroleum by products

and where high temperature upto +180°C are requirement. The Spiral

wound high tensile galvanized iron / Stainless Steel inner wire and

outer wire for providing strength & the flexibility to maintain hose

integrity under stress and strain.

COMPLIANCE

Multihigh Temperature composite hose are manufactured to suite High Temperature requirement.

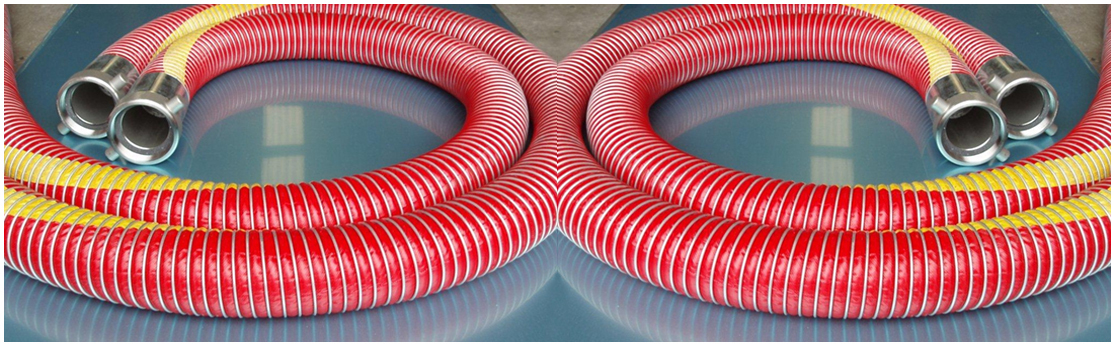

PRODUCT HANDLE

Hot viscous petroleum by-product such as Tar and Bitumen.

FEATURES

- Complete product compatibility for safe handling of all types Hot viscous petroleum by-products such as Tar and Bitumen.

- Heat Resistant Fiberglass fabric outer cover.

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Suitable for 0.9 Bar Vacuum rating.

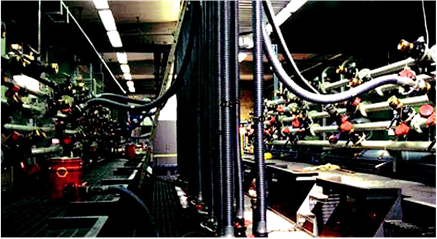

CONSTRUCTIONS

- INNER WIRE : High tensile strength galvanized steel or Stainless Steel

- OUTER WIRE : High tensile strength galvanized steel or Stainless Steel

- CARCASS : Multiple layers of polyamide fabric, film

- COVER : Heat Resistant Fiberglass fabric

- TEMPERATURE RANGE : -30°C to +180°C (However pressure rating will reduce by 50% when temperature exceed 100°C)

- END FITTING : As per client requirement which will be externally crimped or swaged

|

SIZE |

MAX W.P |

MIN. BURST |

BEND RADIUS |

WEIGHT |

MAX. LENGTH |

|||||

|

MM |

INCH |

BAR |

PSI |

BAR |

PSI |

MM |

INCH |

KG/MT |

LB/FT |

MT |

|

25 |

1“ |

10 |

150 |

40 |

600 |

100 |

4 |

1.2 |

0.8 |

20 |

|

38 |

1.5“ |

10 |

150 |

40 |

600 |

150 |

6 |

1.4 |

0.9 |

20 |

|

50 |

2“ |

10 |

150 |

40 |

600 |

200 |

8 |

1.7 |

1.1 |

20 |

|

65 |

2.5“ |

10 |

150 |

40 |

600 |

250 |

10 |

2.4 |

1.6 |

20 |

|

75 |

3“ |

10 |

150 |

40 |

600 |

280 |

11.5 |

2.8 |

1.9 |

20 |

SAFETY

assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with EN 13765.

assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with EN 13765.- Manufacturer test certificate will be provided with the supply.

- Burst pressure Indicated is at ambient temperature.

- Electrically continuity is achieved by the two wire bonded to the end fitting, this helps dissipate accumulated charge and to avoid static flash.