About

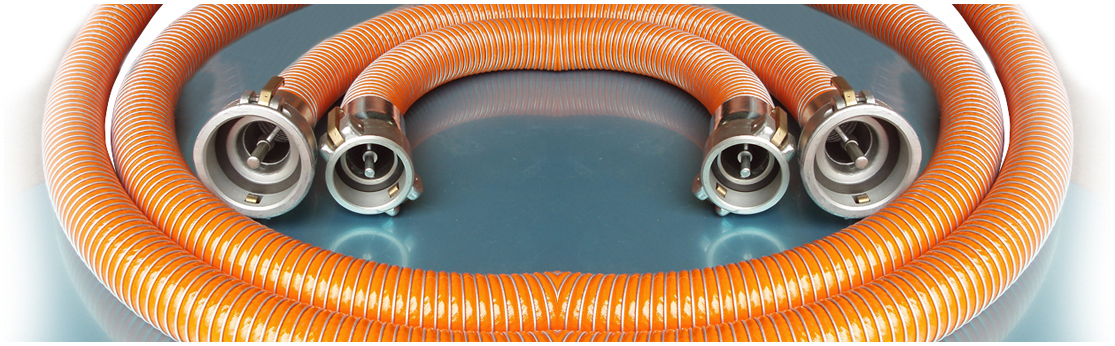

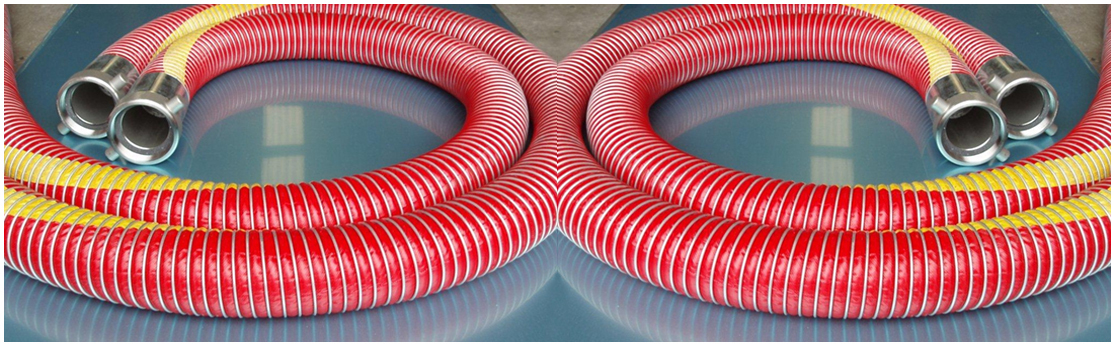

- SHARDA INDUSTRIAL CORPORATION (SIC) is specialized in the manufacturing and Marketing of Composite hose and hoses assemble.

- The company is located at Vasai close to JNPT port, Mumbai India

- SHARDA INDUSTRIAL CORPORATION (SIC) offers the most extensive range of composite hose for the industrial usage –

Brand.

Brand. - The complete range of hoses and fitting are developed, manufactured and tested within the company under stage wise quality control system in accordance to BS EN – 13765

PRODUCT INFORMATION

HOSES CONSTRUCTION

The hoses are constructed from Polypropylene, polyamide & polyester films and fabrics, depending on the application. Outer cover of polyester fabrics duly PVC coated resists to dragging, wear and abrasion also resistance to weather and ozone. For more demanding application PTFE liners are also available to handle more corrosive chemicals.

INTERNAL WIRES

Inner wires provide support and are crust resistance.

The Inner wires available are:

- G : Galvanized steel

- P : Polypropylene coated steel wire

- S : Stainless steel 304 or 316

CARCASS

Inner fabric or film provide resistance to oil, hydrocarbon 100% aromatic content and optimum chemical compatibility for maximum hose service life. Reinforced fabrics & films are provided to withstand the required pressure and protect barrier film layers.

- P : Polypropylene Fabric

- T : PTFE Layer

EXTERNAL WIRES

Outer wires provide overall hoop strength and electrical continuity.

The Outer wires available are:

- a) G : Galvanized steel

- b) S : Stainless Steel 304 or 316

- c) A : Aluminum wire

ELECTRICAL CONTINUITY

Typically, most hose assemblies have full end to end electrical continuity which is achieved by bonding inner and outer wise to the end fittings.

SAFETY

All composite hose assemblies are pressure tested at 1.5 times their rated working pressure before shipment. Test certificate shall be providing with all hose assemblies as per standard.

STANDARDS

Composite hoses comply with International Standard BS EN 13765.

REAL ADVANCTAGE FOR YOUR APPLICATIONS

The Composite hoses are seepage-free and leak-proof; that doesn’t kink or collapse also has great hoop strength, exceptional service life, and offers superior safety and performance.

COMPARED TO RUBBER HOSES AND METAL HOSES.

Composite hoses are extremely light in weight and highly flexible for easier handling. Their multi-layer construction prevents catastrophic failure. Flexibility is retained at low and even cryogenic temperatures. Hoses are protected from corrosion and attack by other liquids, UV and Ozone by their tough PVC impregnated fabric cover.

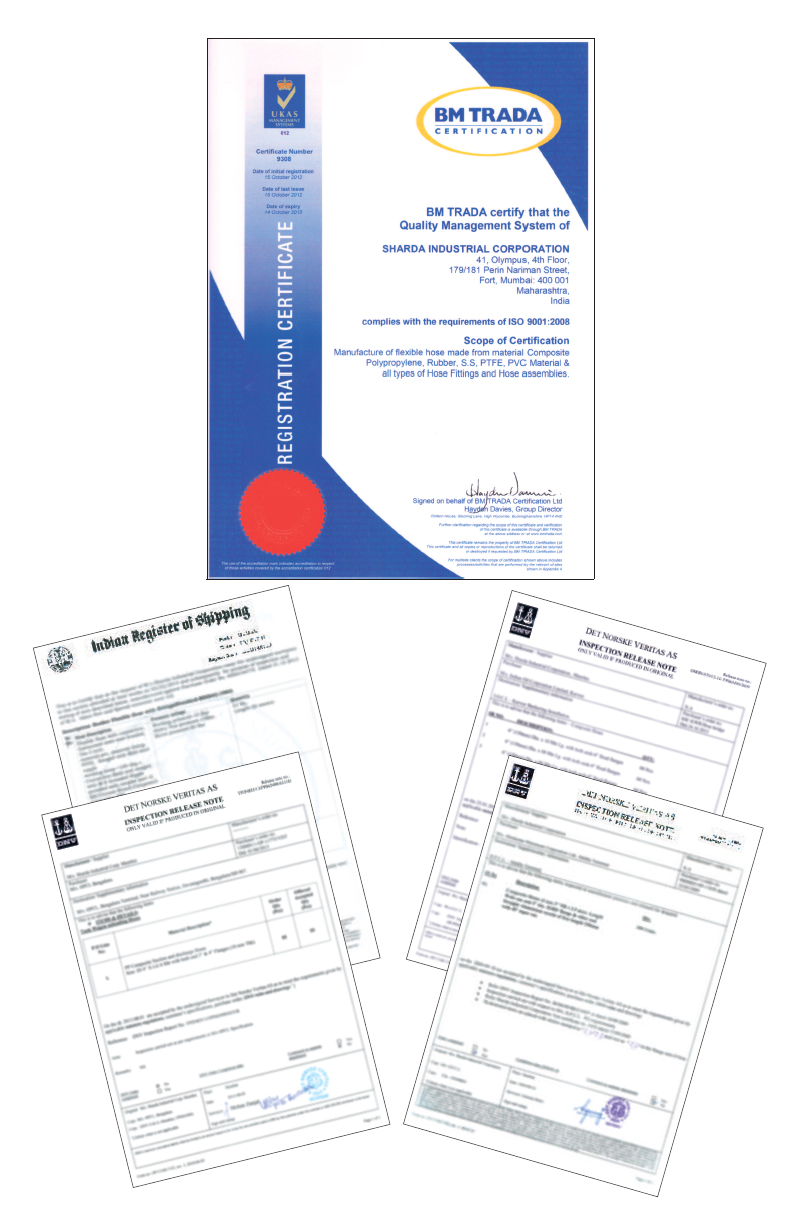

Certificate