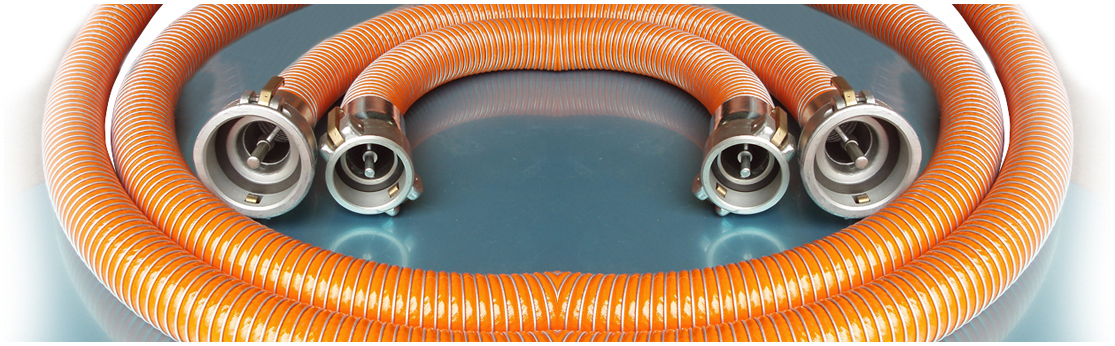

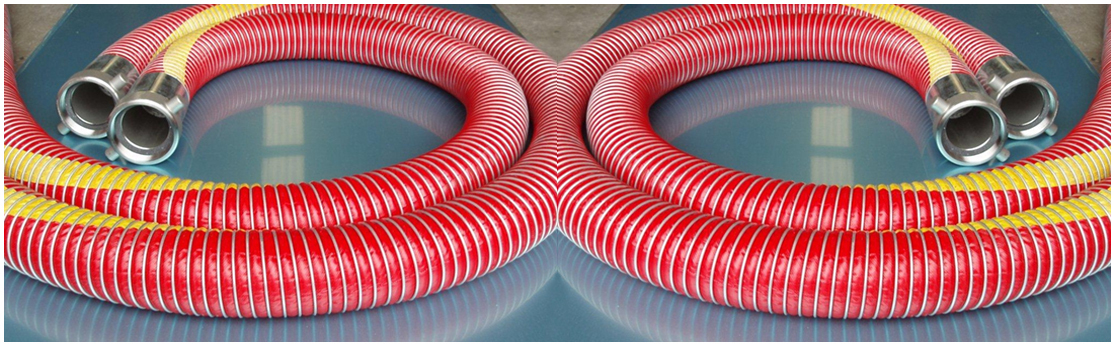

Liquid Petroleum Gas / Liquid Natural Gas Service Cryogenic

HEAVY DUTY

Heavy duty Gas hose are designed especially for transfer of fully refrigerated convey ants like LPG, LNG and their related convey ants in Gas group 4,5,7.

APPLICATION

The  assembly are recommended for fully refrigerated liquefied petroleum

gasses and related conveyants in Gas group 4,5,7. The spiral wound

Stainless Steel 316 inner wire and Stainless Steel 316 under wire for

providing strength & the flexibility to maintain hose integrity

under stress and strain.

assembly are recommended for fully refrigerated liquefied petroleum

gasses and related conveyants in Gas group 4,5,7. The spiral wound

Stainless Steel 316 inner wire and Stainless Steel 316 under wire for

providing strength & the flexibility to maintain hose integrity

under stress and strain.

COMPLIANCE

Gas hose are manufactured and tested in accordance EN 13766 Class A Type 1.

PRODUCT HANDLE

Gas hoses are suitable for transfer Ammonia, LPG, LNG, CNG, Liquid Nitrogen, Propane, Butadiene, Butylenes, Dimethylamide, Ethylamine, Ethyl Chloride, Methyl Acetylene, Methyl Bromide Propane Propadiene, Propylene, Vinyl Chloride, Refrigerant Gases. LPG While Composite hose are suitable for : Liquid Ethylene at -105°C, Liquid Ethane at -88°C

FEATURES

- Maximum compatibility – handles a wide range of low temperature and cryogenic conveyants.

- Reliability – Tested to industry standards 1 ½ time the rated working pressure.

- Durability – Heavy duty Stainless Steel 316 inner and outer wire for maximum chemical and wear resistance.

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Suitable for 0.9 Bar Vacuum rating.

CONSTRUCTIONS

- INNER WIRE : Stainless steel 316 / 304

- OUTER WIRE : Stainless steel 316 / 304

- CARCASS : Multiple layers of Polyamide fabric, film and polyester barrier layers

- COVER : Polyamide fabric

- TEMPERATURE RANGE : -196°C to +50°C

- END FITTING : As per client requirement which will be externally crimped or swaged

|

SIZE |

MAX W.P |

MIN. BURST |

BEND RADIUS |

WEIGHT |

MAX. LENGTH |

|||||

|

MM |

INCH |

LPG |

LNG |

LPG |

LNG |

MM |

INCH |

KG/MT |

LB/FT |

MT |

|

25 |

1“ |

25 |

13 |

100 |

52.5 |

150 |

6 |

1.1 |

0.7 |

20 |

|

38 |

1.5“ |

25 |

13 |

100 |

52.5 |

175 |

7 |

1.8 |

1.2 |

20 |

|

50 |

2“ |

25 |

13 |

100 |

52.5 |

200 |

8 |

2.5 |

1.7 |

20 |

|

65 |

2.5“ |

25 |

13 |

100 |

52.5 |

200 |

8 |

3.9 |

2.6 |

20 |

|

75 |

3“ |

25 |

13 |

100 |

52.5 |

250 |

10 |

4.2 |

2.8 |

20 |

|

100 |

4“ |

25 |

13 |

100 |

52.5 |

500 |

20 |

5.3 |

3.5 |

20 |

|

150 |

6“ |

25 |

13 |

100 |

52.5 |

660 |

26 |

13.5 |

9.0 |

20 |

|

200 |

8“ |

25 |

13 |

100 |

52.5 |

910 |

36 |

21.0 |

14.0 |

20 |

SAFETY

assemblies are tested at 1.5 times rated W.P for safety & reliability.

assemblies are tested at 1.5 times rated W.P for safety & reliability.- Manufacturer test certificate will be provided with the supply.

- Burst pressure Indicated is at ambient temperature.

- Electrically continuity is achieved by the two wire bonded to the end fitting, this helps dissipate accumulated charge and to avoid static flash.