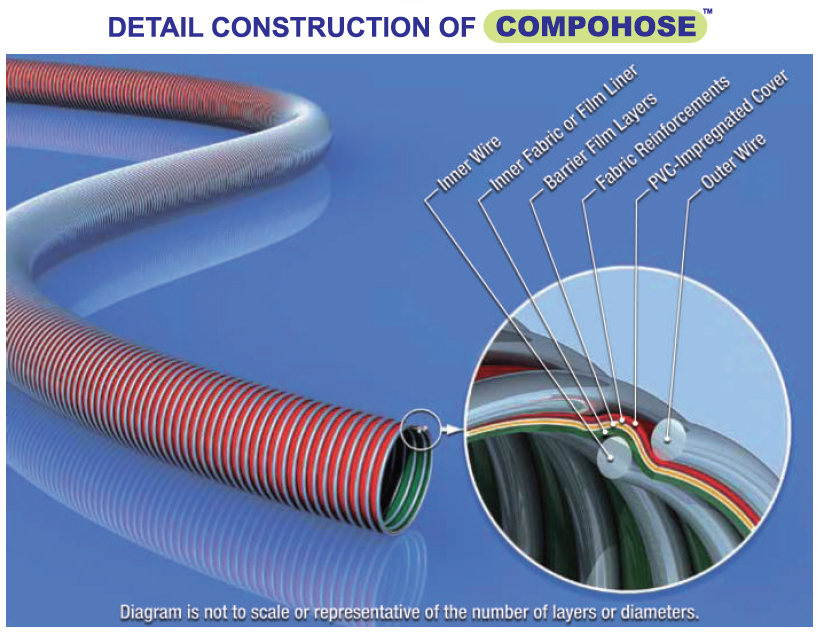

Detailed Construction of COMPOHOSE

TOTALLY ENGINEERED FROM INNER WIRE TO OUTER COVER FOR MAXIMUM SERVICE AND COMPATIBILITY…

Inner wire… provides structural support and crush resistane.

High tensile strength Galvanized Steel, Stainless Steel or special polypropylene-covered inner wire available to provide optimum chemical compatibility and maximum hose service life.

Inner fabric or film liner… provides resistance to chemical attack and protects films layers and end fittings from abrasion. It provides axial strength and greater tensile strength.

Reinforced fabrics provide pressure capabilities and protect barrier film layers.

Reinforcing fabrics and barrier films… handle virtually all solvents, and are compatible with the vast majority of commonly transported chemicals at normal transfer temperatures.

They are unaffected by 100% aromatics and prevent permeation by polar and non-polar liquids.

PTFE liners are available to handle more corrosive chemicals that would attack standard materials.

PVC-impregnated cover… prevents hose abrasion, and provides UV and ozone resistance.

Outer wire… provides over-all hoop strength, structural integrity and double electrical continuity.

Galvanized Steel, Stainless Steel or polypropylene coated is available.

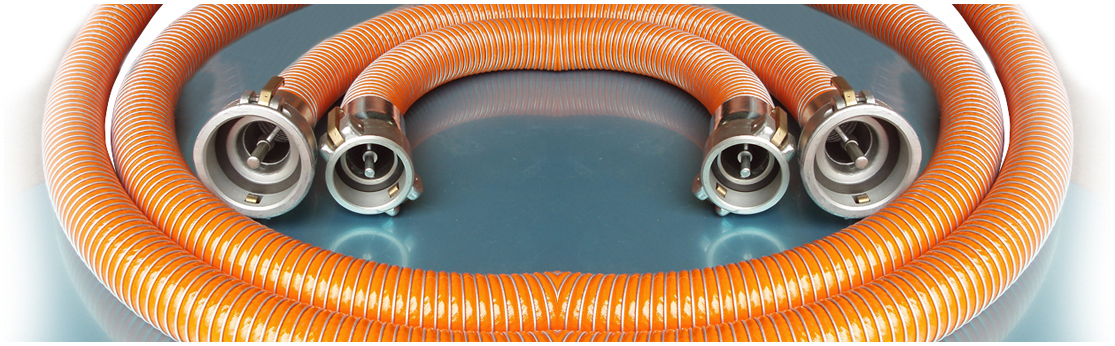

Externally swaged/crimped hose fittings… Achieve perfect union and assure performance up to rated burst pressure.