Handling & Maintenance

The life of hose depends on a number of possibly prejudical factors. Consequently, the end user must carry our periodic preventive maintenance, above all when the condition if use for see high pressure service and/or conveyance of aggressive materials. In any case, when there are indications of possible reduced performance, the product should be changed, or checked carefully at the least.

The following recommendations are the minimum to which the user must adhere.

|

TRACTION: Do not use hose in between (FIG. 1). Let it form a small curve (FIG. 2). |  |

|

TORSION: Hose is not manufactured to work in torsion (FIG. 3). During installation it is essential to ensure that the hose is not twisted. Let it follow an idea lay-line (FIG. 4). |  |

|

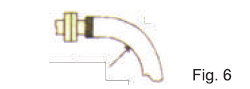

BENDING RADIUS: Installation tighter that the maximum bending radius reduces the life of the hose considerably. Moreover it is necessary to avoid bending close to the end fitting. (FIG. 5&6) |  |

|

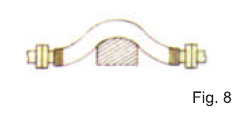

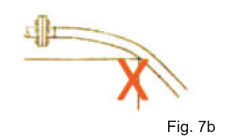

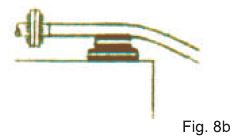

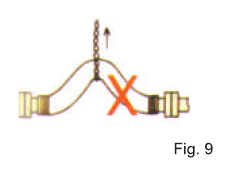

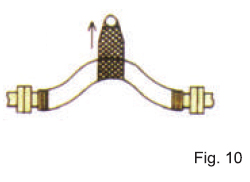

INSTALLATION: The hoses must be supported to allow normal movement when must under pressure (dimensional variations). Do not rest hose on sharp edges (FIG. 7 & 7B). Take adequate precautions (FIG. 8 & 8B). Do not support hoses with ropes or chains (FIG. 9). Flexible hose-supports or polyester slings are recommended (FIG. 10). |  |

|

STORAGE: Hose must be stored in a relaxed condition free from tension, compression or other deformation. Contact with object that could pierce or cut must be avoided. When not is use, hose should be stored in a dark place preferably, avoiding direct sunlight and rain. It must be protected from rodents and insects. When such a risk is probable, appropriate precautions must be taken. |  |

|

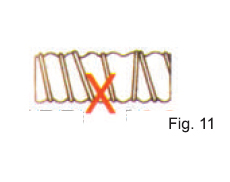

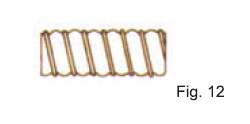

NORMS AND METHOD OF USE: Prior to installation it is necessary to check the characteristics of the hose carefully to ensure that type, diameter and length conform to the required specification. (FIG. 12) Moreover a visual check must be carried out to make sure that there are no obstruction, cuts damaged cover or any other evident imperfections (FIG. 11). Although the hoses are manufactured to guarantee exceptional resistance to abrasion, it is advisable to move them with care, avoiding knocks, dragging over abrasive surfaces or crushing. Furthermore, hoses must not be pulled violently when twisted or knotted. |  |

|

MAINTENANCE: Even when choice, storage and installation is carried out correctly, regular maintenance is necessary. During regular checks, special attention must be paid to couplings and to the appearance of irregularities which can indicate deterioration of the hose. After use, it is advisable to empty the hoses carefully and if necessary, clean thoroughly. We recommend in any case, that the hoses be checked and tested under pressure once a year. |  |

| NEVER weld reduction couplings or flanges onto original hose fitting.

NEVER close or hold the coupling ferrules in a bench vice as they could be deformed. If necessary, hold the hose itself, closing the vice onto the outside spirals of the hose. |