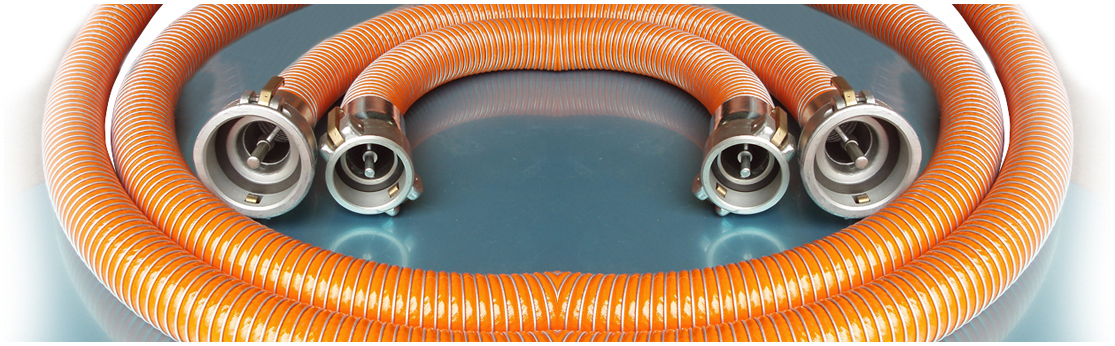

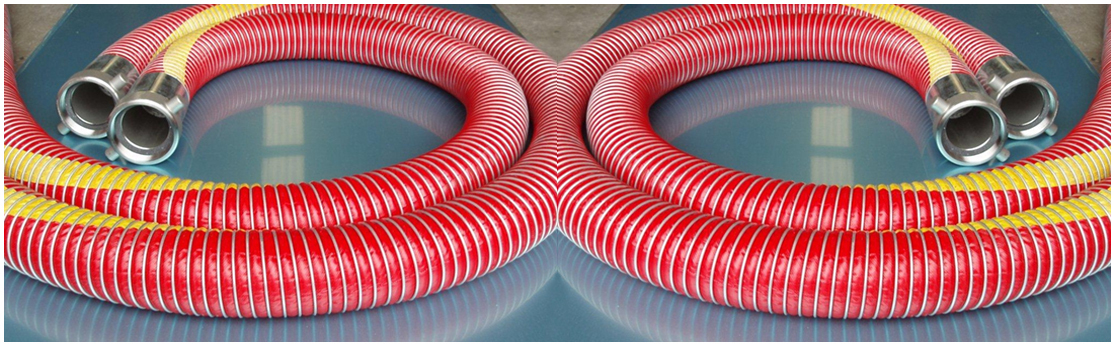

Mulitioil Dock Oil Suction & Delivery

Heavy DUTY-GPG

Heavy duty oil marine hose are designed for handling fuel, lubricant and 100% aromatics at required discharge pressure or suction at port installation.

APPLICATION

The  assembly are recommended for loading and unloading barges, ocean tanker

and bunkering services also recommended for the other dock side

operation at port installation. The spiral woung high tensile galvanized

iron inner wire and outer wire for providing strength and the

flexibility to maintain hose integrity under stress and strain of the

ship and barge movement.

assembly are recommended for loading and unloading barges, ocean tanker

and bunkering services also recommended for the other dock side

operation at port installation. The spiral woung high tensile galvanized

iron inner wire and outer wire for providing strength and the

flexibility to maintain hose integrity under stress and strain of the

ship and barge movement.

COMPLIANCE

Heavy Duty Marine hoses are manufactured and tested in accordance to EN 13765 type 3

PRODUCT HANDLE

Gasoline, Diesel fuel, paraffin, kerosene, lubricaring oils and 100% aromatics as well as black oils and heavy lubricants and solvents.

FEATURES

- Complete product compatibility for safe handling of all types of oil based 100% aeromatic.

- Tough PVC outer cover resists to dragging wear, abrasion, UV and ozone resistance having maximum durability and safety.

- Double end to end electrical continuity prevents static electricity build up and internal arcing.

- Suitable for 0.9 Bar Vacuum rating.

CONSTRUCTIONS

- INNER WIRE : High tensile strength galvanized steel

- OUTER WIRE : High tensile strength galvanized steel

- CARCASS : Multiple layers of polypropylene fabric, film and polyester barrier layers

- COVER : Abrasion resistant PVC impregnated fabric

- TEMPERATURE RANGE : -30°C to +80°C

- FOR CHEMICAL HOSE : Please refer chemical resistance compatibility chart

- END FITTING : As per client requirement which will be externally crimped or swaged

|

SIZE |

MAX W.P |

MIN. BURST |

BEND RADIUS |

WEIGHT |

MAX. LENGTH |

|||||

|

MM |

INCH |

BAR |

PSI |

BAR |

PSI |

MM |

INCH |

KG/MT |

LB/FT |

MT |

|

100 |

4“ |

15 |

200 |

60 |

850 |

400 |

16 |

5.2 |

3.5 |

20 |

|

150 |

6“ |

15 |

200 |

60 |

850 |

575 |

23 |

11.5 |

7.7 |

20 |

|

200 |

8“ |

15 |

200 |

60 |

850 |

800 |

32 |

18.0 |

12.0 |

20 |

|

250 |

10“ |

15 |

200 |

60 |

850 |

1000 |

40 |

25.0 |

16.9 |

12 |

SAFETY

assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with EN 13765

assemblies are tested at 1.5 times rated W.P for safety & reliability in accordance with EN 13765- Manufacturer test certificate will be provided with the supply.

- Burst pressure Indicated is at ambient temperature.

- Electrically continuity is achieved by the two wire bonded to the end fitting, this helps dissipate accumulated charge and to avoid static flash.